![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

Science Reports

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

Blacksmith

Blacksmiths were mainly men who shaped iron into different tools. Much skill went into each piece of metal they formed. Back then, all the little details were made by hand.

Iron is easiest to shape when it is hot. Therefore it had to be heated in order to make the figure you wanted.

A forge was much like a little fireplace where you would heat the metal. An air blower would be turned to pump oxygen creating a bigger flame in the forge. A smoke hood would help to keep the fire hot and the smoke away from the face. The metal would heat up under the coals in the forge at a temperature sometimes reaching 400 to 500 degrees. You only needed to put the part that needed the shaping in the flame.

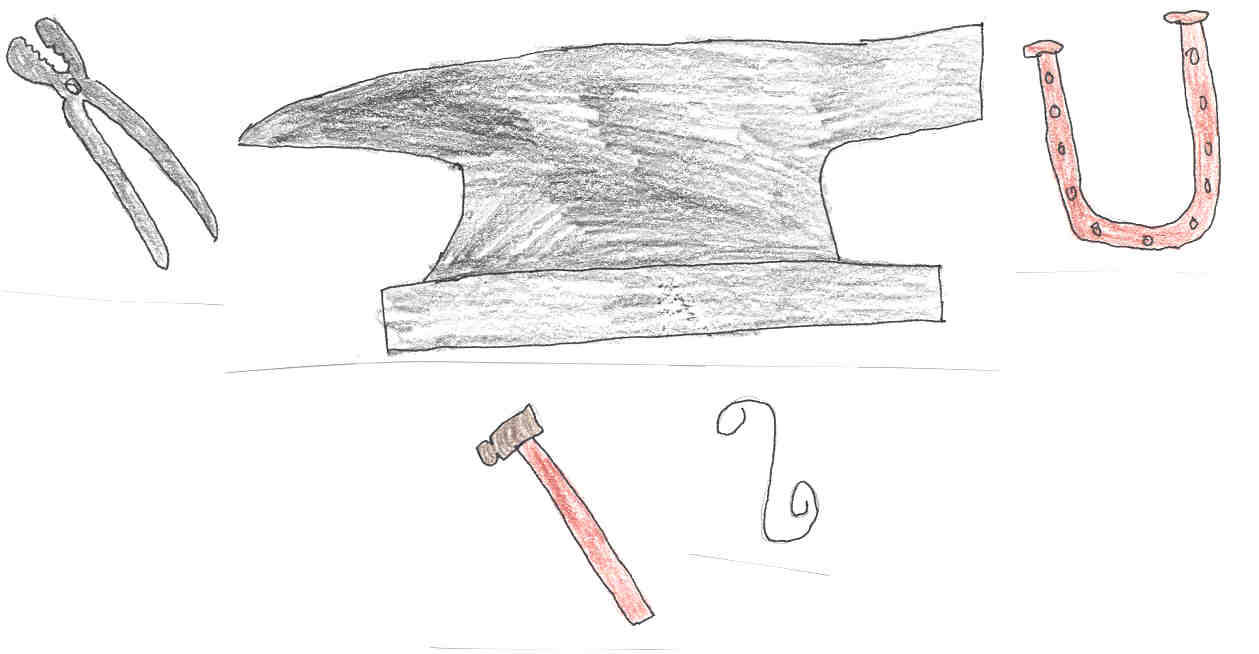

An anvil was used as the basic Shaper of metal. The back of the anvil was flat for sharp edges and the front was round for a circular Pattern. Tongs held the hot metal while shaping on the anvil. Different tongs would give the iron different shapes.

Many various hammers created the shape wanted. By hammering one side you could create a flat surface. Constant rotation of the metal and hammering could create a round iron rod, By placing the iron in a swage block and hammering you could make different figures.

If a blacksmith needed an extra hand he would use a vise. A vise is similar to a clamp. It holds materials the blacksmith is working on. A screw could adjust the grip. You could tighten and loosen the grasp.

A drill press was an easier way of making holes. Instead of having to heat up the iron and puncture a hole you could just rotate the wheel and viola, you have a hole.

Blacksmiths were very useful people. Since many tools were made out of iron, you can get what you needed fixed just by going to the blacksmith.